|

|

WoodworkingHobby.Com! Home of Hobbyist Woodworker Dennis Slabaugh

|

|

Face Frame Biscuit Joiner Jig ©2004 Dennis Slabaugh, Hobbyist Woodworker |

|

|||

|

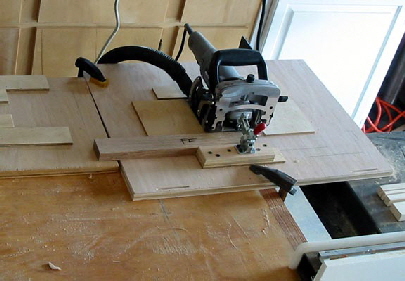

One of the benefits of the Porter Cable biscuit joiner is it’s ability to join face frame stock less than 2” in width. The problem you face,(no pun intended!) is making an accurate cut on the stile end grain of your hardwood stock (quarter sawn white oak) and in the right place along the rail. This challenge of slotting the end of even a 2 or 3” piece of stock while keeping the joiner from wandering off center under the turning force of the spinning blade can be a daunting task as well. Here is the solution: While I built this jig for a kitchen full of face frames, I would take the time to build the jig even for a small face frame project. Perhaps you might think I am strange for saying that sometimes I enjoy the challenge of building a time saving jig as much as I enjoy the project itself! But, we all know that accuracy in our woodworking is what makes it a practical and enjoyable hobby. Jig CONSTRUCTION OF THE JIG As you can see from the top photo, the rail slotting part of the jig is built from scraps of 3/4 inch and 1/4 inch plywood. The idea behind the design is to “capture” the base of the Joiner and the rail receiving the slot. With that accomplished the only other objective is to position the rail and hold it in place. The stock is also “Captured” with the 1/4 inch material and the hold-down clamp block. The jig anticipates a consist ant rail and stile width. For the next project I will make the block that captures the stock variable to account for different width stock. To make the jig accurate, I placed the joiner on the base and laid one strip of the 1/4 plywood along the edge while shooting brads to fix them in place. I worked my way around the three sides of the joiner base creating the captive stops to hold the joiner into alignment with the channel capturing the stock.

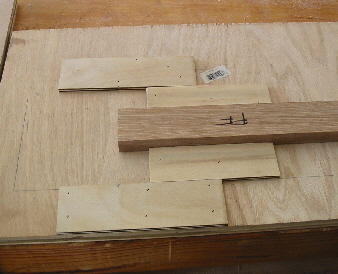

The stile jig shown in the next picture works along the same design idea but the stock is captured and the joiner is “stopped” at the end of the stock. As you can see, it is a very simple jig but essential to centering the slot in such narrow stock USING THE JIG For slotting the end of the stiles and the rails, it is important to mark the FACE side of each piece. This is critical to having a flush joint. The idea is that you create the slot from the same face orientation on each piece because joiner slots are rarely centered in the work piece. This step assures that the joints will come together flush. Seat the jointer flat and square to its “cradle” and slide the stile between the guides until it butts against the machine. Now, just hold the stile tight to the front of the machine with one hand and with the other make the slot. Though I added a hold down clamp for the rail jig, I did not find it necessary for this operation. Making the slots in the rails is just as easy. First mark the centerline of where the slot till lie along the rail. Open the hold-down clamp and slide the stock until it stops in line with the middle of the joiner face (already seated in its “cradle” Lock it down and make the slot. Release the clamp and slide it again until your next slot mark is in line and continue on for as many slots as required. WHAT CAN GO WRONG Forgetting about proper face orientation will result in misaligned slots. I got away with cutting the slot again from the proper face and though the slot was a little sloppy, the joints held strong when they were dry. Warped or bowed stock can create the same problem. Be sure you hold the stock firm and hold it down flush to the plywood jig base. This should improve your accuracy. I have built many face frame projects using mortise and tenon joinery and would not abandon that technique all together. But, with a kitchen full of frames to build, I would use this method again next time.

|

|||

|

[Home] [About Us] [Completed Projects] [New Kitchen] [Workshop] [Information] [Insurance] [Safety] [Panel Cutter] [Face Frame Jig] [News] [FAQ] [Office Project] |

s and systems give us that accuracy.

s and systems give us that accuracy.